A: 70-80 sets.

A: 15 ton. The size is 1.8m * 1.5m.

A: Mould tolerance 0.005mm, Product tolerance 0.01mm.

A: Yes. We have made precision moulds such as moulds for medical devices.

A: Yes. And we have made a couple of BI-injection tools.

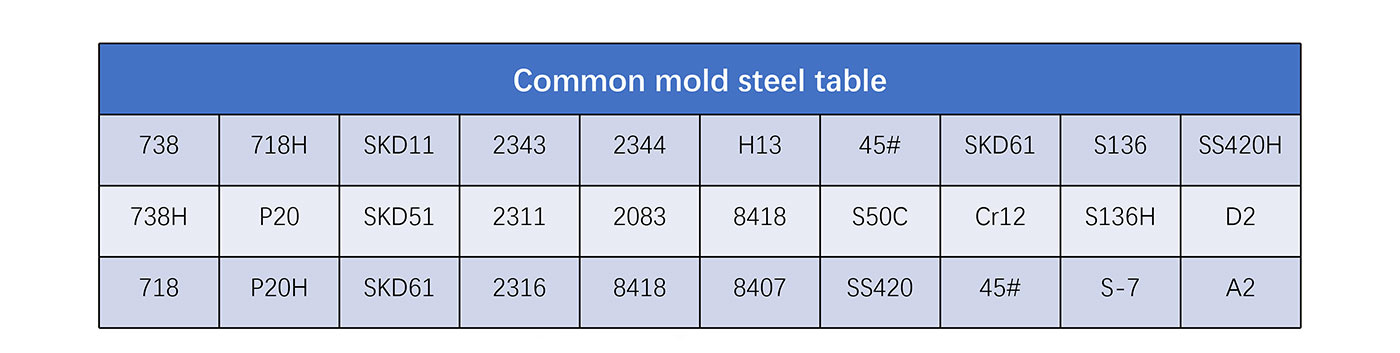

A: We only use raw materials with good quality like P20, P20H, 718H, NAK80,1.2311,1.2378, 1.2344, 1.2767, H13,8407, 420SS, S136, S-7. They are all from famous suppliers, such as LKM, ASSAB, THYSSEN, etc.

A: It’s decided by the customers. We have famous hot runner suppliers locally, such as YUDO, DME, SYNVENTIVE, HASCO,HUSKY, INCOE, EWIKON, MOULD-MASTER etc.

A: We use standard components from LKM,, HASCO, DME, etc.

A: 2D & 3D part files are preferred. Or specific sample with detailed description and mould specification. We use PROE, AUTOCAD, Acorbat Reader, Solidworks, UG and etc. All format related are acceptable.

A: Exact quotation will be available within 2 working days once we get sufficient information from customer.

A: Usually 4-8 weeks. It also depends on mould size and structure complexity.

chat now